Introduction: Why RPD Design Matters More Than Ever

Removable Partial Dentures (RPDs) are among the most challenging restorations in dental technology. Every clasp, rest, and connector must be planned with precision, balancing function, esthetics, and patient comfort. For many dental labs in the United States, RPD cases consume significant time, require specialized expertise, and often become a production bottleneck.

The rise of digital CAD workflows has made RPD design more predictable—but it has also increased the need for trained CAD designers who truly understand removable prosthetics. Maintaining an in-house team with that level of specialization can be expensive and difficult to scale.

That’s why more labs are turning to outsourcing RPD CAD design. By partnering with expert CAD teams abroad—particularly in Mexico—labs can gain access to specialized knowledge, lower costs, and faster turnaround, all while focusing on what they do best: production and client service.

This guide explores everything labs need to know about RPD outsourcing, its benefits, and how it can transform your workflow.

What Is RPD CAD Design?

RPD CAD design is the process of digitally creating frameworks for removable partial dentures using advanced software like Exocad or 3Shape.

An RPD design includes:

- Major connectors (palatal or lingual bars/plates)

- Clasps and rests for retention and support

- Saddles for edentulous areas

- Meshwork or retention grids

- Reliefs, blockouts, and finishing lines

The result is a precisely engineered 3D file (STL or proprietary project) ready for CAM production through casting, milling, or 3D printing.

While crowns and bridges may be considered “bread and butter” cases, RPDs require a deeper understanding of prosthodontics, biomechanics, and digital tools. That’s why outsourcing them to specialists can be a huge advantage.

The Challenges of In-House RPD Design

Many U.S. labs struggle to keep RPD design in-house. Common obstacles include:

- Shortage of skilled technicians – RPD CAD design isn’t something every designer can do. Finding (and keeping) qualified staff is difficult.

- High cost of training and retention – Teaching staff to master partial frameworks takes time, money, and ongoing education.

- Slow turnaround times – Complex cases can monopolize in-house designers, creating bottlenecks.

- Software investment – Exocad or 3Shape modules for partials are expensive and require constant updates.

- Fluctuating case volume – Some weeks bring many RPDs; others only a few. Keeping full-time staff for inconsistent demand is inefficient.

These challenges make outsourcing not just convenient, but often necessary.

The Top Benefits of Outsourcing RPD CAD Design

1. Access to Specialized Expertise

Outsourcing partners in Mexico work on RPD cases daily. They understand clasp design, biomechanics, and digital workflows. For U.S. labs, this means instant access to specialized knowledge that may be difficult to develop internally.

2. Faster Turnaround and Greater Efficiency

Instead of tying up your designers for days, outsourcing partners can return complete RPD designs in 24–48 hours. This ensures patients don’t wait longer than necessary, and labs stay on schedule.

3. Lower Costs and Higher Margins

Hiring an RPD specialist in the U.S. can cost thousands per month in salary and benefits—on top of software and hardware costs. Outsourcing allows labs to:

- Pay per case instead of fixed salaries.

- Avoid expensive software licenses.

- Improve margins by lowering design costs without compromising quality.

4. Scalability Without Risk

RPD demand fluctuates. With outsourcing, labs can scale up during busy seasons and scale down during slow weeks—without hiring or layoffs.

5. Focus on Core Strengths

By outsourcing design, labs free their staff to focus on manufacturing, finishing, and client service. Instead of struggling with CAD design, teams can deliver better restorations and improve dentist relationships.

How Outsourcing From Mexico Provides Extra Advantages

Why Mexico? For U.S. labs, outsourcing south of the border offers unique benefits:

- Cost efficiency – Structural differences in labor and operating costs translate into significantly lower design fees.

- Shared time zones – Easy communication during business hours. No overnight delays like with Asia-based outsourcing.

- Bilingual communication – Many Mexican designers communicate fluently in English.

- Proximity and trust – Nearshore outsourcing (Mexico → U.S.) offers greater reliability compared to distant offshore solutions.

A Typical Workflow for Outsourced RPD Design

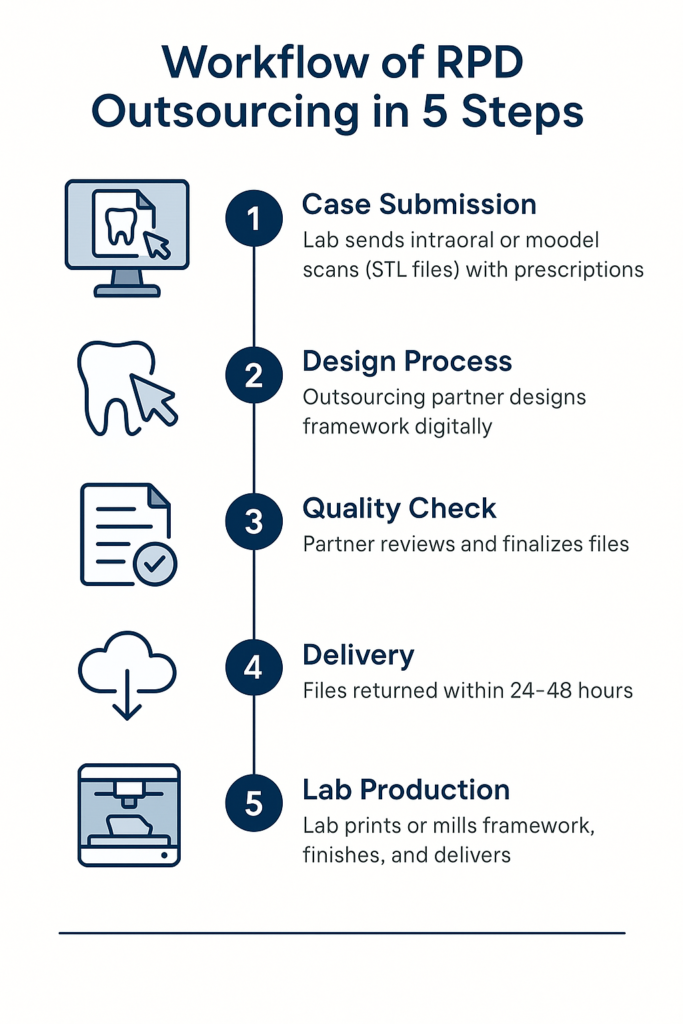

Here’s how outsourcing RPD CAD usually works:

- Case submission – The lab sends intraoral scans or model scans (STL files) with prescriptions and preferences.

- Design process – The outsourcing partner designs the framework digitally (in Exocad or 3Shape).

- Quality check – The partner reviews and prepares the final project files.

- Delivery – Files are returned within 24–48 hours.

- Lab production – The U.S. lab prints or mills the framework, finishes it, and delivers to the dentist.

This workflow makes outsourcing seamless—labs keep full control over final production.

Cost Comparison: In-House vs. Outsourced RPD Design

| Expense Category | In-House (U.S.) | Outsourced CAD (Mexico) |

|---|---|---|

| Designer salary + benefits | $4,500–$6,000/month | — |

| Software licenses (Exocad/3Shape partial module) | $500–$700/month | Included |

| Hardware & updates | $2,000+ amortized | Included |

| Training & turnover costs | Ongoing | Included |

| Cost per RPD case | $200–$300+ (true overhead) | $70–$150* |

| Fixed monthly overhead | $5,000–$7,000 | $0 |

* Exact case pricing depends on complexity and volume.

This table shows how outsourcing turns unpredictable, high fixed costs into predictable, variable costs.

Risks and How to Mitigate Them

Outsourcing is powerful, but it must be managed well. To succeed:

- Choose reliable partners – Review portfolios, request test cases.

- Set clear design standards – Define preferences for clasps, rests, connectors, etc.

- Use structured communication – Standardize case submission with forms and notes.

- Maintain quality control – Always review files before production.

- Protect confidentiality – Use NDAs and secure file transfer systems.

Handled properly, risks are minimal and benefits outweigh them significantly.

Conclusion: The Future of RPD Outsourcing

For U.S. dental labs, outsourcing RPD CAD design is not just a way to cut costs—it’s a strategy to improve quality, efficiency, and scalability. By leveraging specialized teams in Mexico, labs gain access to expert designs, faster turnaround, and a leaner workflow that keeps them competitive.

As digital dentistry continues to expand, outsourcing RPD design ensures labs can handle complex removable prosthetics without the burden of in-house specialization.

👉 If your lab is ready to streamline RPD workflows and deliver more consistent results, outsourcing CAD design may be the smartest move you make this year.